عنا

مرحبا هل يمكنني مساعدتك؟

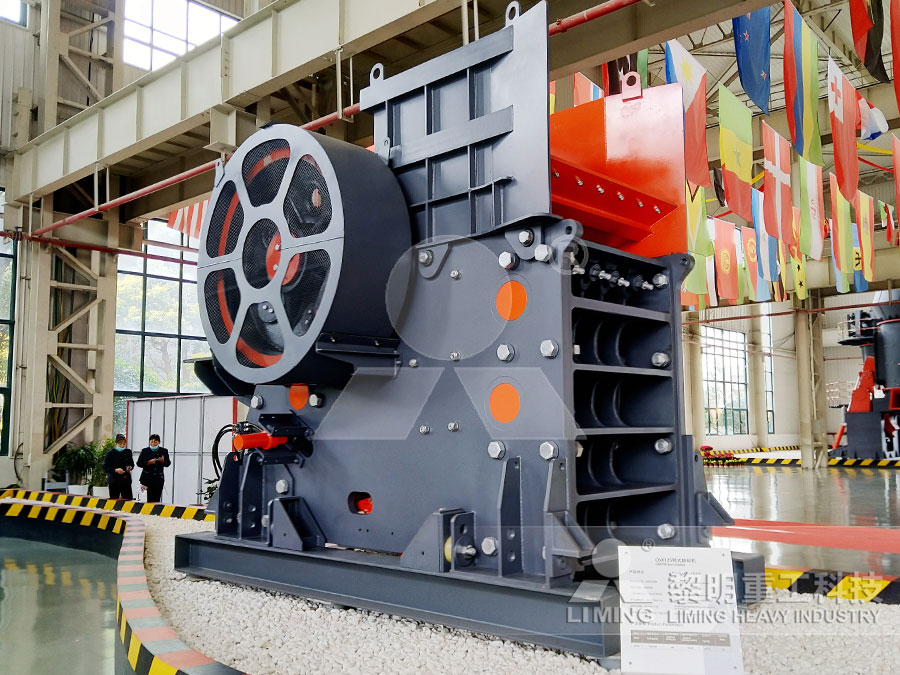

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

feed size ball mill wikipedia cement ball mill nstruction.pdf

2021-01-20T05:01:22+00:00

Ball mill Wikipedia

A ball mill is a type of grinder used to grind, blend and sometimes for mixing of materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering It works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement Most cement is currently ground in ball mills and also vertical roller mills which are more effective than ball millsCement mill Wikipedia F 80 is the mill circuit feed size in micrometers Rod mill A rotating drum causes friction and attrition between steel rods and ore particles [citation needed] But note that the term 'rod mill' is also used as a synonym for a slitting mill, which makes rods of iron or other metal Rod mills are less common than ball Mill (grinding) Wikipedia

Grinding in Ball Mills: Modeling and Process Control

52 the milling process takes place during rotation as a result of the transfer of kinetic energy of the moving grinding media into the grinding product The design of a ball mill can vary significantly depending on the size, the equipment used to load the starting material (feeders), and the system for In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do Often, the ball used in ball Calculate and Select Ball Mill Ball Size for Optimum Grinding The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum ‘chunk size’, product size Ball Mill Design/Power Calculation

The cement mill

Cement manufacturing brief description of a cement mill Cement clinker is usually ground using a ball mill This is essentially a large rotating drum containing grinding media normally steel balls As the drum rotates, the Cement grinding Vertical roller mills versus ball mills Soeren Worre Joergensen MSc, • the feed to a cement mill is often completely dry and is significantly more By these measures it has been possible to obtain particle size distributions for cement ground in OK mills similar to those for cement ground in ball mills (BM Cement grinding Vertical roller mills versus ball millsconstruction design of ball mill pdf bondhumahalin construction design of ball mill pdf construction design of ball mill pdf construction design of ball mill pdf , Ball mill Wikipedia, the free encyclopedia A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints , Contact Supplierconstruction of ball mill pdf

Rawmill Wikipedia

The remaining dusty gas is usually returned to the main kiln dust control equipment for cleaning Feed size can be up to 100 mm Roller mills are efficient, using about half the energy of a ball mill, and there seems to be no limit to the size The effect of Ball Mill RPM speed going from subcritical to supercritical helps understand the Ball Mill Working Principles of ballonball VS ballonshell grinding The Motion of the Ball Charge The input energy in ball milling is that applied by the drive to impart motion to the mill chargeBall Mill Critical Speed Working Principle YouTubeCement Ball Mill Material And Energy Balance Full Project Most cement is currently ground in ball mills and also material balance on cement mill pdf cement ball mill material and energy balance full project design pdf Get Price And Support Online; Energy Balance For Roller Mill Used In Cement ball mill cement pdf

TECHNICAL NOTES 8 GRINDING R P King

material in the mill including the media which may be steel balls in a ball mill, or large lumps of ore in an autogenous mill or a mixture in a semiautogenous mill, as well as the slurry that makes up the operating charge Let Jt be the fraction of the mill volume that is occupied by the total charge, Jb the fraction of the mill volume thatCement mill Wikipedia The grinding action employs much greater stress on the material than in a ball mill, and is therefore more efficient Energy consumption is typically half that of a ball mill However, the narrowness of the particle size distribution of the cement is problematic, and the process has yet to receive cement grinding ball mill particle size reduction Mill construction details A ball tube mill may be described as a cylinder made of steel plates having separate heads or trunions attached to the ends with each trunion resting on suitable bearings for supporting the machine The trunions are hollow to allow for the introduction of discharge of the materials undergoing reduction in sizePulverizer Wikipedia

cement ball mill wikipedia

cement ball mill pdf indianaminingcoza Ball mill Wikipedia The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory material, fertilizer, glass ceramics, etc as well as for ore dressing of , click to chat nowSummary The Ball Mill is designed to grind materials by turning the cylindrical shell with grinding medium (eg steel balls) put in the shell, and has a simple structure and ease of handling Furthermore, The Ball Mill of a large capacity Ball Mill SlideShareBall mill 1 Contents Principle Construction Working Applications Advantages Equations governing the operating speed 2 Ball mill consist of a hollow cylindrical shell rotating about its axis Axis of the shell horizontal or at small Ball mill SlideShare

work of ball mill pdf

Cement mill Wikipedia A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball millsEnergy Saving Ball Mill * Product Introduction A high efficiency and energy saving ball mill with rolling bearing * Capacity Up to 160t/h * Product Improvement Cylindrical energy saving grid ball mill is lined grooved ring plate which increases thWhat is a ball mill? What are its uses and advantages? Cement mill Wikipedia A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball millswork of ball mill pdf

detail about ball mill wikipedia Exodus Heavy Machinery

detail about ball mill wikipedia,Ball mill A typical type of fine grinder is the ball millA slightly inclined or horizontal rotating cylinder is partially filled with balls usually stone or metal which grind material to the necessary fineness by friction and impact with the tumbling balls Ball mills normally operate with an BallRod Mills, based on 4″ liners and capacity varying as 26 power of mill diameter, on the 5′ size give 20 per cent increased capacity; on the 4′ size, 25 per cent; and on the 3′ size, 28 per cent This fact should be carefully kept in mind when determining the capacity of a Steel Head BallRod MillBall Mills Mineral Processing Metallurgy OK™ cement mill The most energyefficient mill for cement grinding Quality and cement vertical roller mills, and in comparison with traditional ball mill operations, the energy requirements for the OK cement mill is if the mill feed is very hot, the mill exit temperature controls a damper for cold air intake One mill, OK™ cement mill The most energy efficient mill for cement

Ball Mill SlideShare

If the rate of feed increased, coarser product will be obtained and if speed of rotation is increased the fineness for a given capacity is increases During grinding, the balls themselves wear and are continuously replaced by new ones so that mill contains balls of various ages Ball mill produces 1 to 50 ton/hr of powder and energy requirement The High Energy Ball Mill E max and MM 500 were developed for grinding with the highest energy input The innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest amount of time with only minor warming effects These ball mills are also suitable for mechano chemistryBall Mill RETSCH powerful grinding and homogenization How to Size a Ball Mill Design Calculator Formula and F80 and P80 are the sizes in micrometers that 80% of the weight passes of the mill feed and product respectively Ball milling – a ball mill with a diameter of How to Size a Ball Mill Design Calculator Formula

VSI mill Wikipedia

Superior selectivity of minerals liberation in Titan M mill as compared to conventional ball mills (for example, copper oredressing with Titan VSI mill yields 17,6% copper concentrate with 82,6% extraction as compared to 14,5% and 76,1% obtained with a ball mill grinding, respectively)A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that it can be rotated along its longitudinal axis The balls which could be of different diameter occupy 30 50% of the mill volume and its size depends on the feed and mill Ball Mill: Operating principles, components, Uses, See this useful summary Table of Bond Work Index by Minerals For any circuit, whether a crushing circuit, a rod mill, or a closed ball mill circuit, the Work Index always means the equivalent amount of energy to reduce one ton of the ore from a very large size Bond Work Index FormulaEquation